PRODUCTION CAPABILITIES

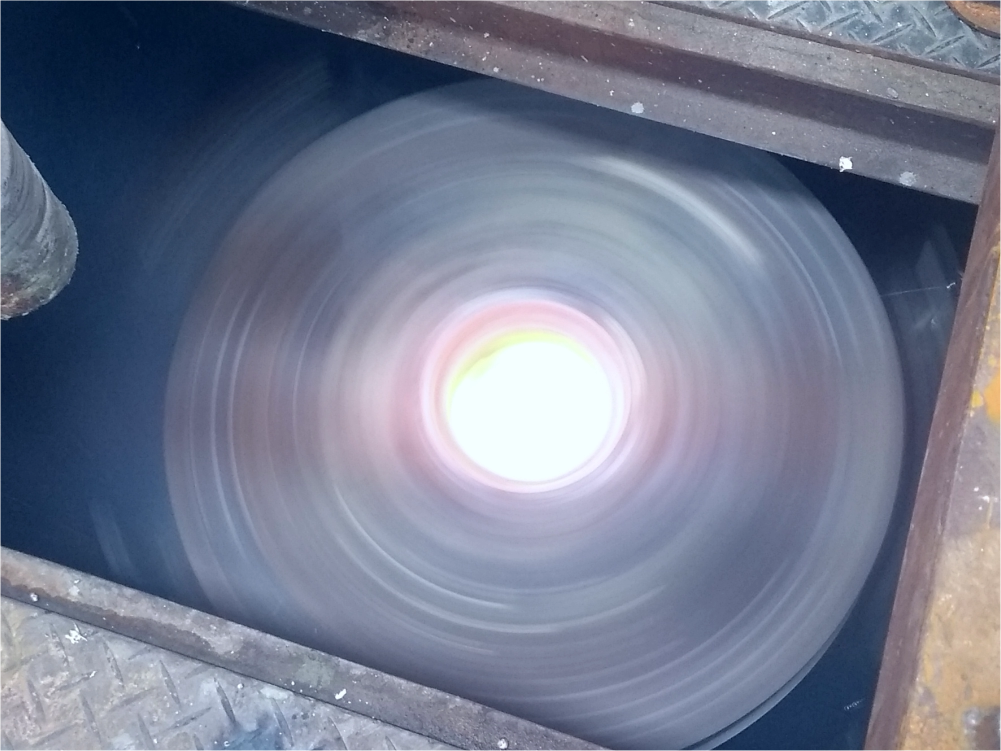

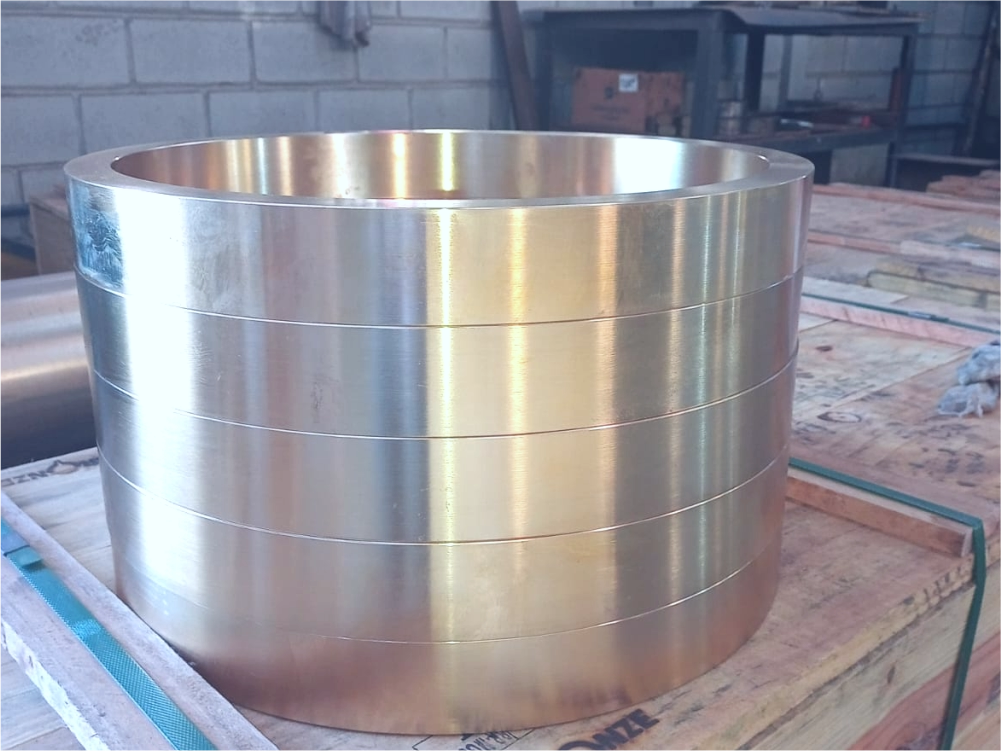

CENTRIFUGAL CASTING

The centrifugal casting is used in the production of bushings, tubes and rings.It guarantees parts with a homogeneous and refined metallic structure and provides greater mechanical resistance to the material.

Horizontal centrifuge for rings and bushings up to Ø 32″;

Vertical centrifuge for rings and bushings up to Ø 80″;

DIE CASTING

Die casting consists of dropping molten metal into metal molds. It is used to obtain thicker parts with simple shapes, such as plates, billets and bars. Regularly shaped parts, a refined metal structure and less machining are all advantages of this process.

Durvile – for plates measuring up to 8″ X 20″ X 60″

Static Molds for billets, rulers and bars;

SAND CASTING

The sand casting process produces parts with complex geometries for the most diverse purposes. Using this method, FundiBRONZE produces parts up to 2.5 tons according to the project. If necessary, we provide customers with the project of the pattern and take care of its manufacture.

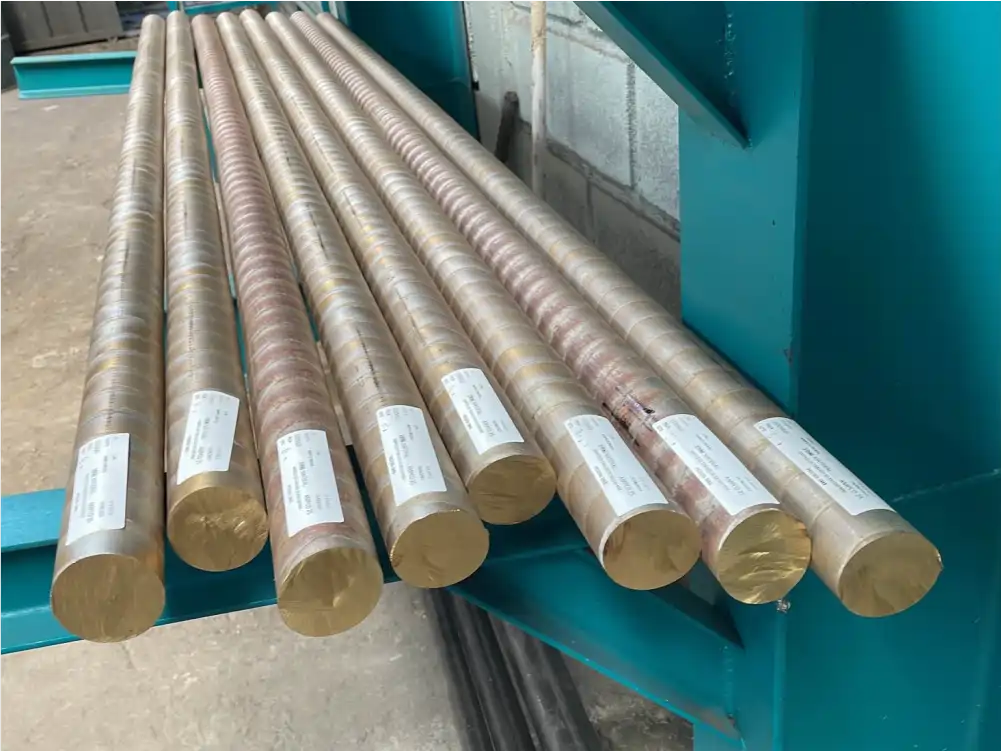

CONTINUOUS CASTING

Using the continuous casting method, FundiBRONZE produces bars and tubes of various profiles in bronze or brass with diameters of up to 5 inches and lengths of up to 4 meters. It has the capacity to produce large volumes at very competitive prices.

HEAT TREATMENT

In many copper alloys, obtaining the required standard characteristics is only possible by applying heat treatments after the part has been produced. FundiBRONZE, through the AMPCO Group, has extensive know-how in this area and has the infrastructure to carry out the necessary heat treatments in-house: a 2 cubic meter furnace, a cooling tank, a system for determining and recording the temperature curve and a small furnace for testing.

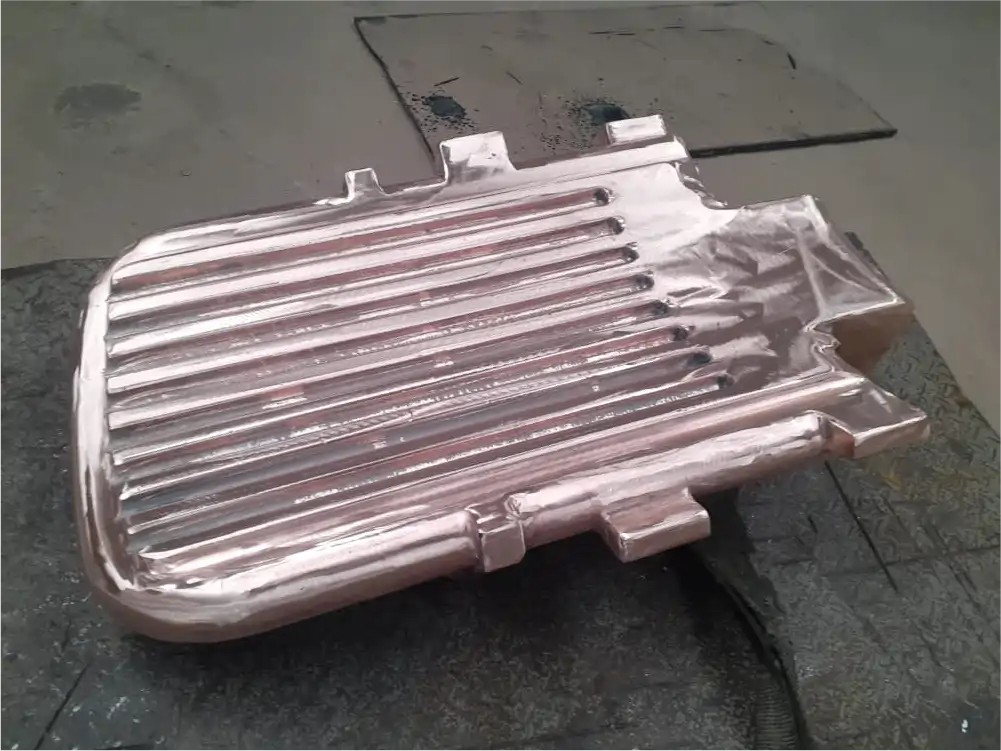

WELDING

Soldering copper alloys is a delicate process that requires materials, techniques and qualified professionals. FundiBRONZE’s welding department assembles the welded elements specified in the project, as well as coating parts with copper alloys and recovering worn parts.

MACHINING

FundiBRONZE has its own modern machining facility, well equipped with machining centers, lathes, boring and milling machines, as well as various dimensional control equipment. The company offers fully machined or pre-machined parts.

Contact

Address: Rua do Horto, 511 – Dist. Industrial

CEP 35681-779 – Itaúna/MG

+55 (37) 3242-9170

[email protected]

Address: Rua do Horto, 511 – Dist. Industrial

CEP 35681-779 – Itaúna/MG

+55 (37) 3242-9170

[email protected]

Representatives

Rio Grande do Sul

Santa Catarina

São Paulo

Minas Gerais (BH, other regions)

Minas Gerais (Steel Valley and Northern Minas Gerais)

Representatives

Rio Grande do Sul

Santa Catarina

Eriberto Serafim – (47) 99961-9164

São Paulo

Carlos Nascimento – (11) 95897-0364

Minas Gerais (BH, other regions)

Minas Gerais (Steel Valley and Northern Minas Gerais)

Fabiano Nascimento – (81) 99116-9594